Vulcanization agent poly alkyl phenol disulfide VA-TB710

Composition:Para-tert-butylphenol disulfide(90 % ) + sulfur(< 3 %)+stearic acid(10%)

CAS NO.:60303-68-6

Synonym:

Mixture of tert-butylphenol disulfide polymer and stearic acid;

Arkema Vultac TB710 equivalent;

Poly-tert-butylphenol disulfide;

poly-alkyl phenol disulfide polymer;

alklyphenol disulfide polymer;

Para-tertiobutylphenol Disulfide Polymer; Alkylphenol disulfide polymer;

Para-tert-butylphenol disulfide polymer;

Tert-butylphenol disulfide polymer;

Alkylphenol disulfide polymer sulfur donor;

Alkylphenol disulfide oligomer;

Curing Resin

Specification:

| Item |

Standard |

Test Way |

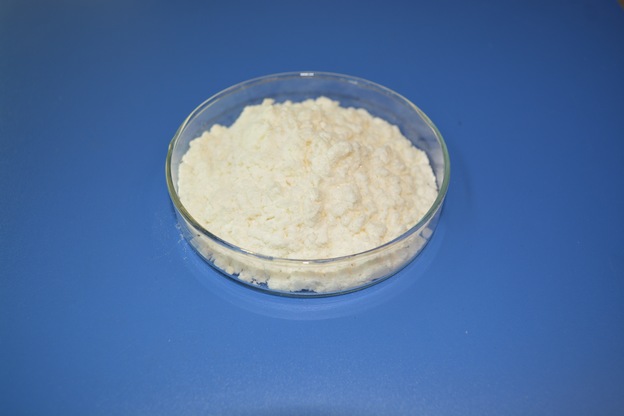

| Appearance |

brown pastilles or powder |

Visual |

| Sulfur content, % |

26.4-28.4 |

Combustion |

| Softening point, ℃ |

75-95 |

Ring & Ball |

| Stearic acid content,% |

9.0-11.0 |

FTIR |

Application:

① Alkylphenol disulfide polymer VA-TB710 is a Sulfur donor for natural and synthetic rubbers.

② Alkylphenol disulfide polymer VA-TB710 produces a high percentage of mono-sulfidic crosslinks that results in vulcanizates with superior aging characteristics.

③ Alkylphenol disulfide polymer VA-TB710 can be used as either complete or partial replacements for sulfur and thiuram and DTDM sulfur donors in EV and semi-EV type cure systems.

④ In tires Alkylphenol disulfide polymer VA-TB710 is used in the inner-liner, chafer,bead apex, sidewalls, and tread.

⑤ Industrial applications include noise damping blocks, motor mounts, dock fenders, elastic threads, automobile engine hoses, gaskets, belts, and other industrial rubber products that require good heat resistance.

⑥ Alkylphenol disulfide polymer VA-TB710 also aid in rubber processing.

⑦ Alkylphenol disulfide polymer VA-TB710 polychloroprene vulcanizates have improved flex life.

⑧ Alkylphenol disulfide polymer VA-TB710 is also an excellent bleaching agent,antioxidant,catalysts in the disproportionation of rosin or rosin esters.

① Dosage: 0.5~20 phr.2 phr is most preferably

Characteristics:

① Polymers: Natural rubber and synthetic elastomers. Especially good in curing rubber that contains chlorine such as chlorobutyl and polychloroprene.

② Synergism: Can be used with most typical rubber accelerators and sulfur. When used as a partial replacement for sulfur, Alkylphenol disulfide polymer TB710 tends to improve dispersion of other additives in the rubber.

③ Crosslink Type: Alkylphenol disulfide polymer TB710 promotes mono-sulfidic crosslinks resulting in vulcanizates with excellent heat and aging resistance.

④ Non-nitrosamine: Alkylphenol disulfide polymer TB710 does not produce nitrosamines like many of the other sulfur donors such as DTDM and the thiurams.

Advantages:

① Non-nitrosamine

② Lower tack to make it easier to stock and handle

③ Lower volatility

④ Lower volatile degradation products

⑤ Good compatibility with many rubber polymers

⑥ Very good antioxidant properties

⑦ Improve heat age properties of vulcanizates because of its generation of mono- and di-sulfic crosslinks

⑧ Increase the resinous plasticizer during processing

⑨ Increase the green tack in NBR,BR and SBR based compounds

⑩ Improve the dispersion of other compound ingredients into rubber

Package:

25kgs/paper drum;25kgs/kraft bag or as customer’s request;

Storage:

It should be stored in dry & cool environment(below 86 °F/30℃) in closed original containers.

Shelf Life:

2 years if stored as indicated above